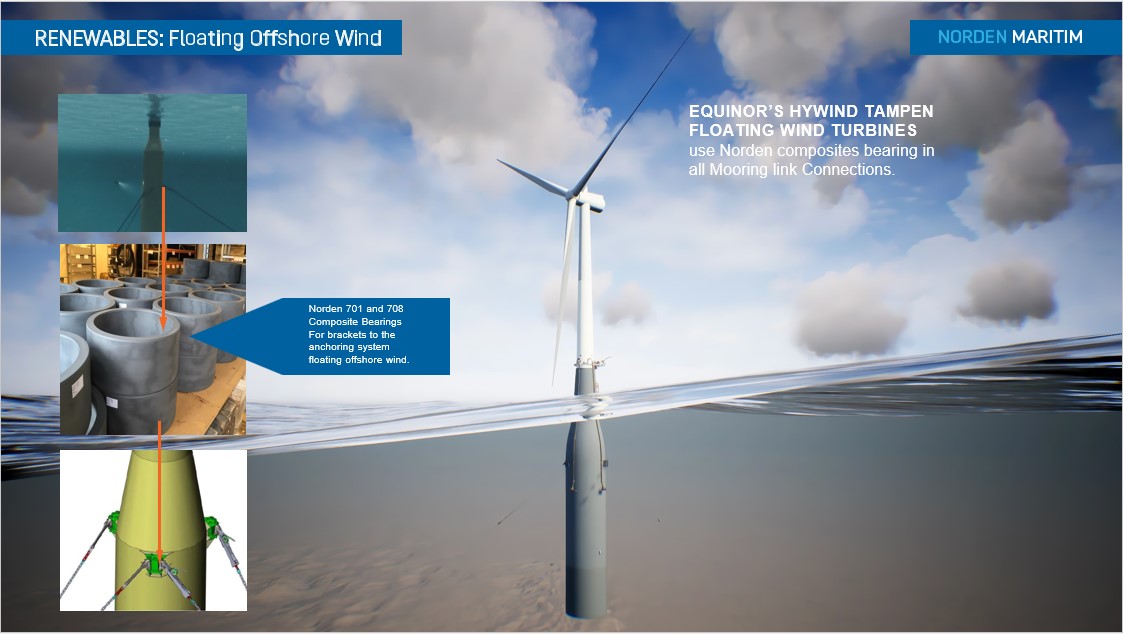

Composite bearings materials are at the core of what we do. And we do them well.

OIL & GAS

Bearings for offshore cranes & drilling equipment

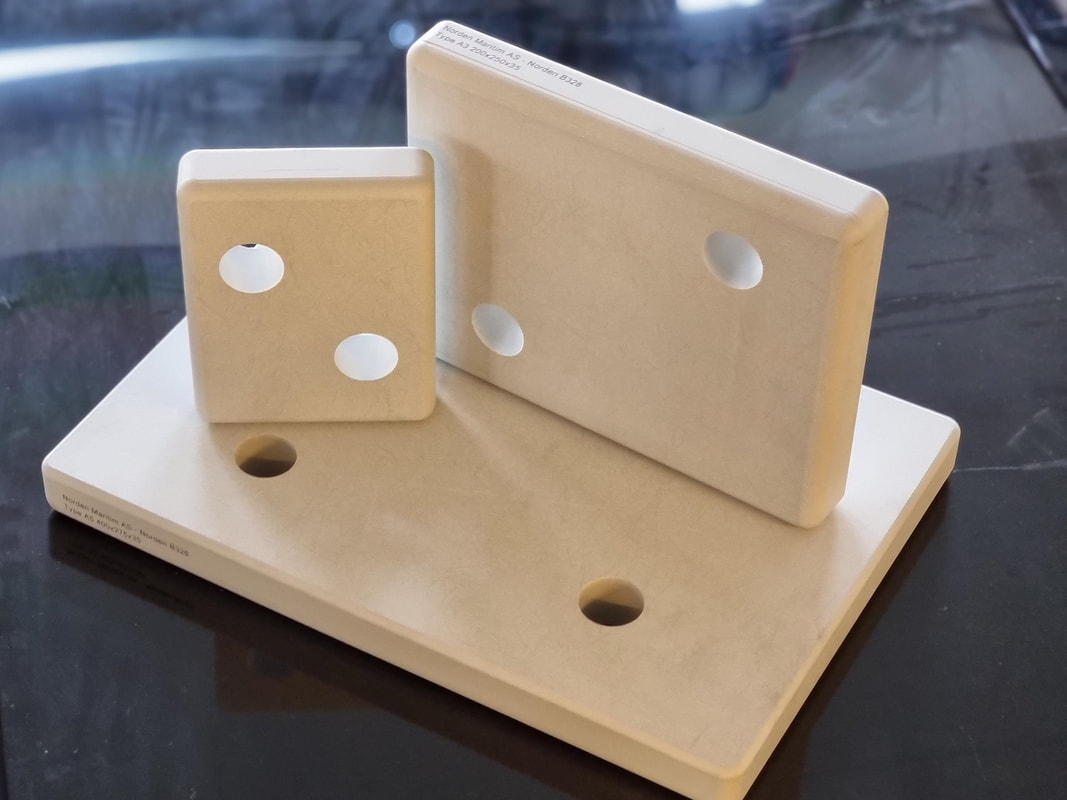

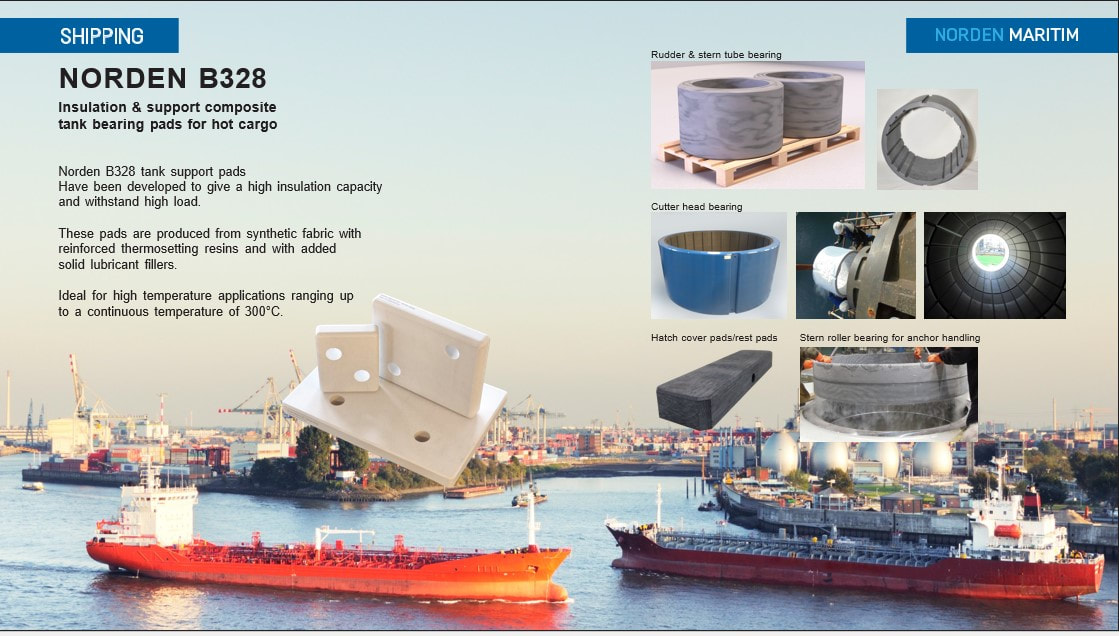

SHIPPINGInsulation & support tank bearing pads for hot cargoNorden Bend Restrictor and Buoyancy Element SystemWear rings and stripsRENEWABLES - OFFSHORE WINDDREDGING INDUSTRY |

MARITIME products

Turret bearings Chain guide shoe Offshore cranes & drilling Wear rings and strips MATERIALS Norden 788 Norden 701 Norden 901 Norden 988 Norden AM8 Norden NFF Norden RA5 Norden 605 Norden CM7 Norden CM77 Norden CM10 NORDEN 422 CPR |

Freeze Fitting

|

1: Select or manufacture a thin wall steel container which can be clad with insulating material around its outside diameter, the container should be just large enough to hold the bearing and allow it to be completely immersed in the liquid nitrogen.

2: Place the bearing into the container then start to pour in the nitrogen. For the first few moments the nitrogen will boil off as soon as it contacts the steel surface. Once the steel surface has cooled sufficiently the nitrogen will start to fill the container. 3: Due to the extreme temperature differential the liquid nitrogen will continue to boil off for some time during this period it will be necessary to keep topping up the container ensuring the bearing is completely covered by the nitrogen. 4: When the boiling has subsided, the bearing should be left to stand in the nitrogen for a further period of time. This will be dependant upon the bearing size and can vary from a minimum of 10 minutes for small bearings, up to 90 minutes for large bearings. |